Company Policy

- Determined to deliver high-quality and hygienic packaging products for your highest satisfaction

Express Plaspack (Thailand) Co., Ltd. was found in 1996 with registered capital of THB 70 million by Mr. Aphicha Thaworn-amornsri, Managing Director and Mrs. Phakkaphorn Thaworn-amornsri, Assistant Managing Director. We have two manufacturing facilities: (1) Head Office and Samutprakarn factory located at 1480 Moo 9 Tagnrodfaisaikao Road, Teparak, Muang Samutprakarn, Samutprakarn province on a 3-rai land and (2) Samutsakorn factory located at 14/9 Moo 2 Banphaeo-Prapatone Road, Chaimongkhon, Muang Sumutsakorn, Samutsakorn on a 8-rai land, completed since 2018.

Prior to establishing Express Plaspackl (Thailand), Mr. Aphicha had been the managing director of T.Charoen Industry Co., Ltd. since 1987. The company was engaged in manufacturing PE shrink film for major players in food and consumer products industry. In 2003, Mr. Aphicha expanded the business into Flexible Packaging area to support the potential growth in food sector of Thailand. In addition, many enterprises started to realize the importance of plastic packaging for superior product appearance, high standard, good hygiene, and enhanced competency for global competition.

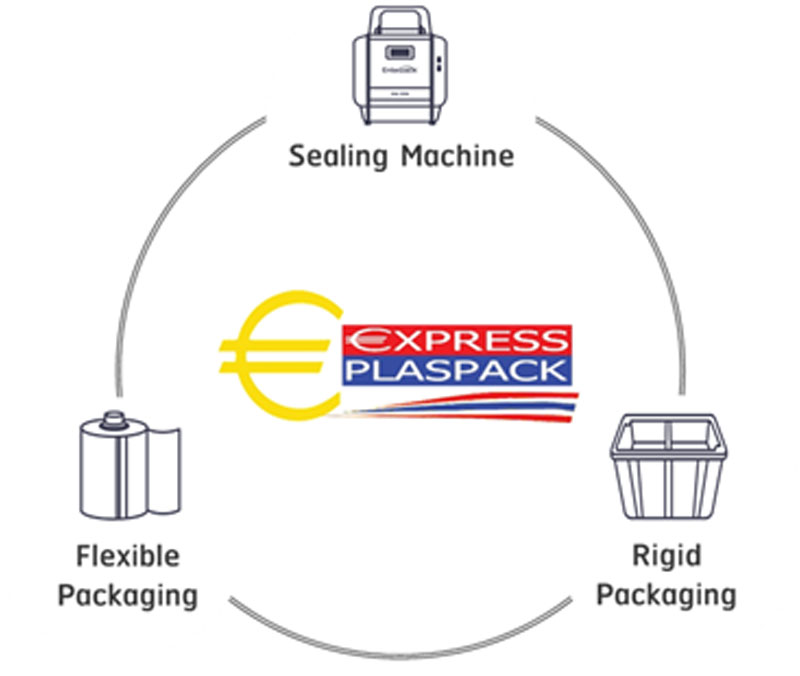

In 2015, the company established a new factory in Samutsakorn province and ventured into Rigid Packaging area for plastic container line of products as to meet the rising demand for ready-to-eat meals and frozen food. In 2017, the company set up SMART PACKTM product line by designing and importing the automatic tray sealing machine – the compact and affordable instrument that can address the business issues and increase competitiveness for SMEs and startup in ready-to-eat food industry.

We are proud to be the selected supplier for a number of leading food producers in Thailand and we determined to continuously improve our quality and deliver hygienic packaging products for all customer’s highest satisfaction. At present, Express Plaspack (Thailand) Co., Ltd. has registered capital of THB 140 million with combined production capacity for Flexible Packaging and Rigid Packaging of over 120,000 tons per year. The British Standard Institute (BSI) has certified the company for ISO9001:2015 Quality Management System, Good Manufacturing Practice (GMP) and HACCP for MANUFACTURER OF FLEXIBLE PACKAGING AND SHRINK FILM OF NON FOOD AND FOOD PRODUCTS.

The company put main policy on the research and development with aim to increase preservable shelf life and protect food products, in turn enabling the opportunity for exports to regional and global markets. That goes in line with the government campaign: “Thai kitchen to the World”.

Company founded

Established the head office and factory in Samutprakarn province for Flexible Packaging product line

Purchased and installed a 5-layer coextrusion cast line machinery from Germany

Developed Lid Film Easy Peel & Antifog for CPF Group

Established the factory in Samutsakorn province for Rigid Packaging product line

Ventured into Sealing Machine product line

We have strong emphasis on research and development activity. We are driven to increase our packaging’s feature for food protection and preservation for better shelf life so that our customers can export food products abroad without shelf life constraint, enabling the government’s vision “Thai kitchen to the World”.

After the kick off of Flexible Packaging line in 2003, the company in 2004 imported and set up 5-layer film coextrusion cast line technology from Windmöller & Hölscher (W&H), Germany. The technology was well renowned among plastic copnverters globally for its ability to produce stable high-barrier multilayer film that incorporates various polymers and materials of up to 5 different layers. This results in remarkably transparent film and superior quality, i.e. lower risk for film delamination and leakage, minimize adhesive and solvent residuals. The film is also easy to process and excellent for vacuum packing application. In addition, special functionalities can be added per customer’s requirements; for example, easy-peeling and anti-fogging properties.

At present, we are a total solution provider for Flexible Packaging within the food and beverage sector. Our products are used in many applications, including fresh food, frozen food, instant meal and ready-to-eat meal. We currently have the total manufacturing capacity of over 50,000 tons per year.

Urbanization trend has encouraged city dwellers to form “single family” with fewer people in a household and live in condominiums. In addition, the digital age tends to have “on the go” lifestyle and prefers convenience and speed to any traditional lifestyle. Therefore, “frozen food and ready-to-eat meals” become the answer to such metropolitan lives. We, as a food packaging company with our long expertise in Flexible Packaging, hence realize the opportunity and develop Rigid Packaging product line as to meet the rising demand in the coming era. In 2015, we ventured into Rigid Packaging business segment by establishing the second factory in Samutsakorn province on a 8-rai land.

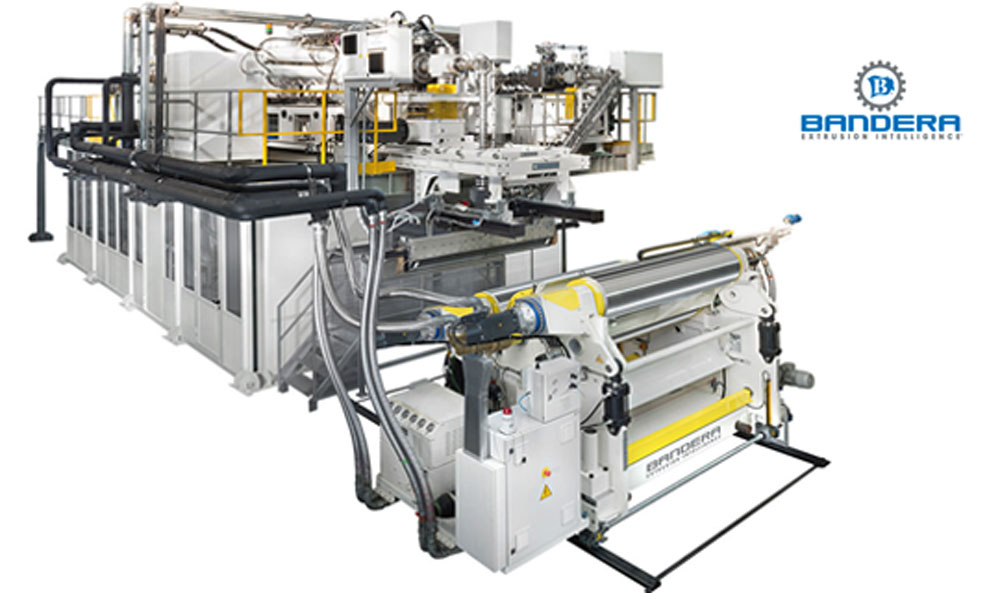

We imported twin screw extruder technology from Luigi Bandera, Italy for the production of quality PET sheet which serves well for form-fill & seal thermoforming (FFS) application. In addition, we also invest in PP material thermoforming production line to strengthen our Rigid Packaging area. At present, we are a leading manufacturer of plastic food containers such as tray, box, cup, and bowls that can be sealed with our Flexible Packaging products, thereby enhancing product shelf life for our customer’s food products.

This website uses cookies to improve user experience. By using our website you consent to all cookies in accordance with our privacy policy. เราใช้คุกกี้เพื่อพัฒนาประสิทธิภาพ และประสบการณ์ที่ดีในการใช้เว็บไซต์ของคุณ คุณสามารถศึกษารายละเอียดได้ที่ นโยบายความเป็นส่วนตัว